Materials Needed:

- Blackjack Clay Natural Kiln Fire Stoneware

- Potter’s Wheel

- Bat

- Water Bucket

- Sponge

- Wooden Rib Tool

- Wooden Knife Tool

- Fettling Knife

- Trimming Tool

- Shammy

- Wire Tool

- Scoring Tool

- Giffin Grip Bat

- Kiln

- Cone 10 High Fire glaze

Preparing The Clay

Wedge

Weigh out desired amount of clay. (1 pound of clay was used for this sample mug.)

Prepare the clay by wedging it.

*Wedging is the process of pushing and pressing on clay to expel all air bubbles

trapped in it and to bring the clay to a uniform, consistent moisture level.

Step 1

Centering

Form clay into a sphere and slam it onto the center of the bat attached to the potter’s wheel.

Wet hands and clay.

Turn the potter’s wheel on and center the clay.

Step 2

Open The Form

Insert one finger to start into the center of the clay. Using fingers firmly pull the clay back towards the body creating an opening in the clay. Repeat several times until the clay is the desired width.

Step 3

Compress The Floor

Use the wooden rib to compress the floor of the form. Insert the wooden rib tool into

the opening and pull the tool back towards the body.

Step 4

Walls

Pull the clay up from the bottom in-between fingertips to create the walls of the

form. Repeat until walls are the desired thickness and height.

Step 5

Base

Use the wooden knife tool to trim away excess clay from the bottom of the form to shape the base of the mug.

Remove the excess clay with a felting knife.

Step 6

Rim

Smooth the rim of the mug with a wet shammy.

Step 7

Removal

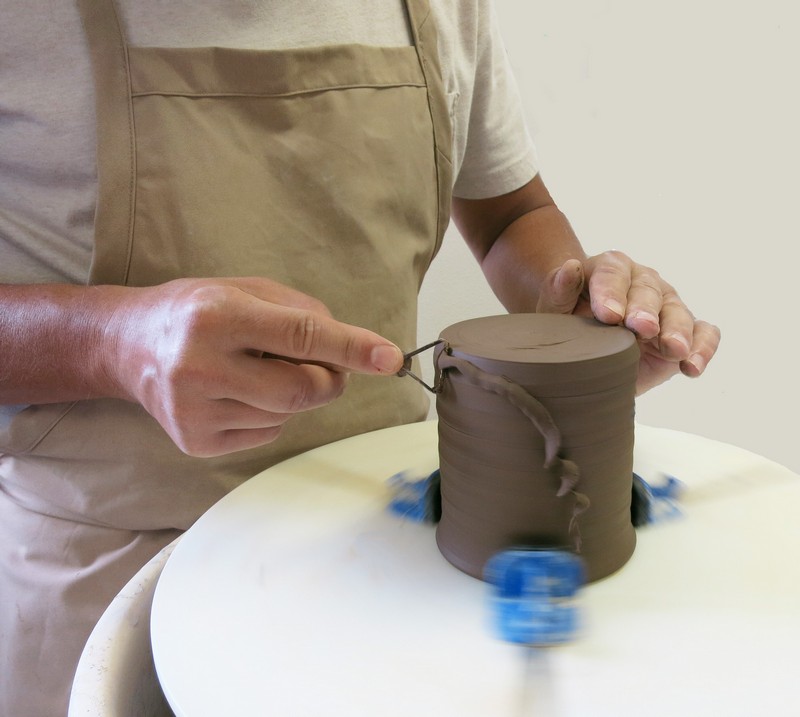

Slip a wire tool under the base of the mug and cut the mug off of the pottery wheel bat.

Step 8

Dry

Allow the clay to dry to a leather hard state.

*Leather hard clay is clay that has started to dry but has some flexibility; it can still be carved, cut, and joined together, but it is hard like a block of cheese.

Step 9

Handle

Roll a thick cone out of clay.

Dip the clay cone into the bucket of water.

Remove clay from the water and begin to pull the clay downward from the top with fingertips. Keep stretching the clay downward until the clay reaches the desired length and thickness.

Set the handle aside to stiffen up before attaching it to the cup form.

Step 10

Trim

Position the leather hard cup into the Griffin Grip bat. Remove excess clay from the base of the cup form using the trimming tool.

Smooth the foot of the mug with a damp sponge.

*Handle Continued

Score the area where the handle will be connected to the cup.

Score one end of the handle and apply clay slip.

Smooth the two pieces of clay together with fingertips.

Repeat the process for the bottom of the handle. Cut off the excess clay with a felting knife.

Step 11

Thumb Rest

Roll a small sphere of clay. Score and slip it onto the top of the handle. Gently press thumb into the clay until it flattens the clay to a comfortable thumb rest shape.

Step 12

Dry

Allow the clay to bone dry.

*Bone Dry is clay from which as much water as possible has evaporated from the

piece; if you hold it to your cheek, it will seem dry instead of cold and damp. This clay

looks and feels chalky and is very fragile; it is at this stage that clay pieces are fired in

the kiln.

Step 13

Bisque Fire

Fire the clay mug in the kiln to bisque fire temperature.

*Bisqueware is an unglazed clay piece that has been fired in the kiln once at a low

temperature and is ready to be glazed.

Step 14

Glaze

Apply a high fire glaze to the bisque mug.

Step 15

Glaze Fire

Fire the glazed mug in the kiln.

*Glazeware is a clay piece that has been fired twice - once in a bisque firing and a second time in a glaze firing; it has a glossy or matte glasslike finish and a smooth texture.