Supplies Needed:

- Sandtastik High Strength Plaster Premium Casting Compound

- Measuring cup

- Mixing container

- Water

- Spoon

- Bear shape mold

- Tray

- Paper clip

- Sandpaper

- Acrylic paint

- Water bowl

- Paint brush

Step 1

Mixing

Measure compound according to package directions.

*Material is activated by using 2 parts casting material to 1 part cold water.

Mix gently and slowly until a pancake batter consistency is reached.

Step 2

Pour

Place the mold in a tray.

Pour the plaster mixture into the mold.

Gently tap or vibrate the mold on the tray to release any air bubbles.

Large air bubbles can be popped with fingertips.

Step 3

Hook

When the plaster begins to set up, insert a paperclip half way into the plaster.

Step 4

Cure

Allow the plaster to cure. Average setting time is approximately 20-30 minutes.

*The plaster will become warm as it begins to cure and then cool as it completes the process.

Step 5

Removal

Loosen the castings from the mold by gently pulling back on the mold’s edges.

Lift the casting completely out of the mold.

Step 6

Dry

Allow the casting to completely dry.

Drying time will vary depending on temperature andhumidity levels.

The plaster will gradually become lighter in color as it dries.

Step 7

Smooth

File down any rough edges on the bear casting using sand paper or a file.

Step 8

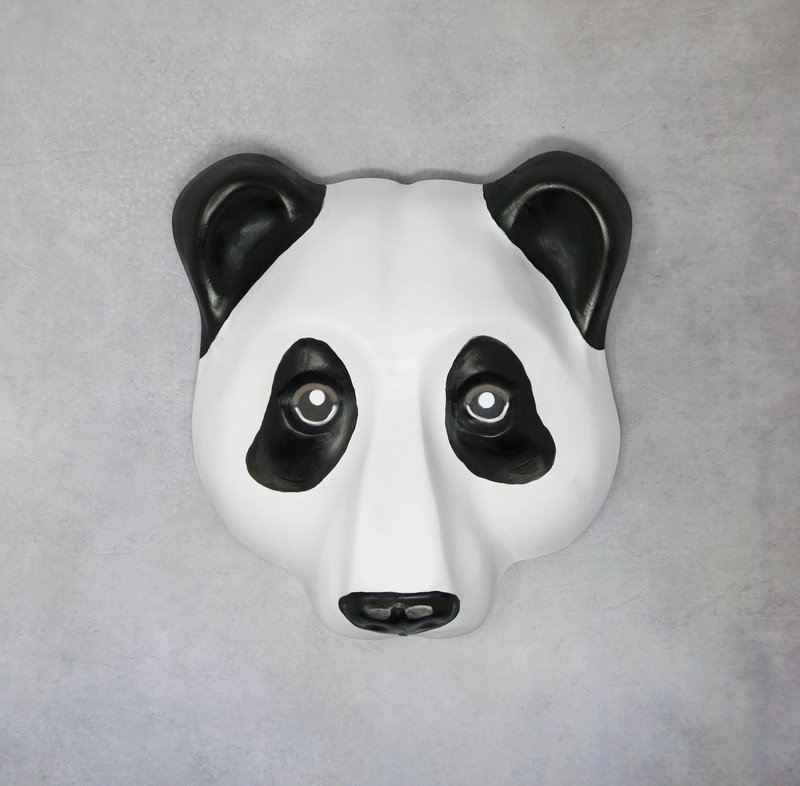

Paint

Paint the bear casting using the acrylic paint.